Learn Why the 360 Precision Hand Truck System Pays off in Less than 30 Days

Save Time and Money

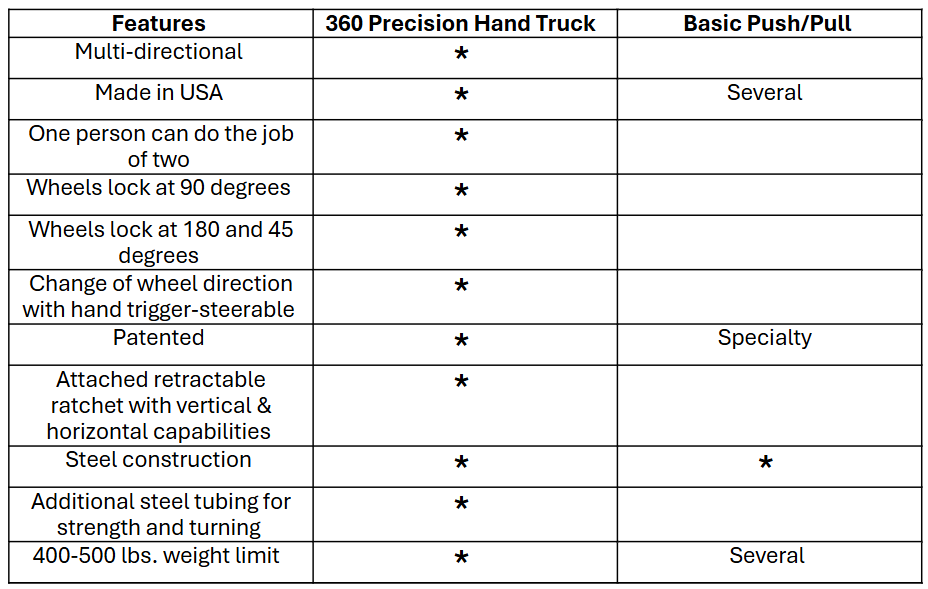

The patented 360 Precision Hand Truck offers all the standard capabilities of a regular push/pull hand truck, ensuring it meets the basic requirements for transporting items. However, what sets it apart is its multi-directional design, which provides a range of additional functions not found in basic, low-cost hand trucks.

The basic design of the push/pull hand truck has essentially been the same since the advent of sack trucks in the 17th century that were used by boys to move sacks of spices from ships in Europe. (https://en.Wikipedia.org/wiki/Hand-truck)

While the price of the 360 Hand Truck is comparable to most specialty hand trucks, it differentiates itself by not being limited to just a single purpose. Unlike most specialty carts, which typically have only one function, the 360 Hand Truck delivers versatility, making it useful for a variety of tasks while reducing injuries.

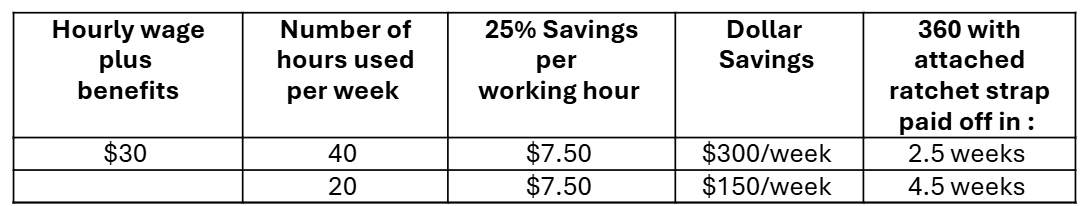

Customers tell us there is an approximate 25% labor savings when the 360 Hand Truck is used. Often, one team member can perform the work of two. Based on these savings, the following payoff schedule is as follows:

In addition, there is less damage to the load and the balloon wheels made for hard surfaces such as flooring and cement won’t scuff the walls.

The 360 Hand Truck product may be more expensive than the basic linear hand truck, but its features, including the ratcheting/retracting strap attachment provides load safety and prevents load damage, crushes, etc.

The 360 system can go a long way in preventing injuries in material handling that can cost companies loss of labor, loss of income, and increased workers’ compensation premiums.

Savings Cost from Injuries

The number one cause of workplace injury for the past several years is overexertion, which accounts for 22.7% of all injuries with a cost to the industry of $13.3 billion a year (a statistic that continues to climb year over year). (Source: Liberty Mutual Safety Index 2025)

Injuries caused by overexertion is followed by falls on the same level, being struck by objects, and other bodily reactions (more statistics that together add up to an additional 35.7% and $20.9 billion in injury costs).

All of the above injury categories are associated with hand truck and material handling use. The most common injuries seen in the workers compensation industry related to hand truck use consist of:

An employee trying to save an awkward load that shifts, risking product falling because of not using good body mechanics. (Potential injuries include bicep tear/separation, rotator cuff tears, shoulder dislocation, hand injury, wrist injuries, elbow injuries, knee injuries, neck sprain/strain and upper or lower back strain/sprain or injury.) *

An employee having to physically lift a hand truck and load to reposition or maneuver around. This often leads to a load shift, which can increase the risk of an employee being struck by falling objects. (Potential injuries include bicep tear/separation, rotator cuff tears, shoulder dislocation, neck sprain/strain, hip injury, knee injury, upper or lower back strain/sprain, hand, wrist and arm injuries and amputation of limbs.) *

An employee being struck by items that fall from a stack while moving. (Potential injuries include bicep tear/separation, rotator cuff tears, shoulder dislocation, neck sprain/strain, hip injury, knee injury, upper or lower back strain/sprain, hand injuries and amputation of limbs.) *

An employee experiencing loss of balance from an awkward maneuvering challenge, resulting in a fall. (Potential injuries include head/CNS injuries, hip fracture, elbow fracture, wrist fracture, hand injury, shoulder dislocation, neck sprain/strain and upper or lower back strain/sprain or injury.) *

An employee suffering an injury when initiating load transfer or shifting weight from the hand truck’s center of gravity to balance on wheels. (Potential injuries include bicep tear/separation, rotator cuff tears, shoulder dislocation, knee injuries, hand injury, wrist injury, elbow injury, neck sprain/strain and upper or lower back strain/sprain or injury.) *

Too many employees sustain back injury or strain when lifting a hand truck to reposition or position the load to change direction. With the Hand Truck 360’s easily transitioning individual wheels, an employee has multiple options to smoothly move a load.

preventing injuries in material management that can cost companies loss of labor, loss of income, and increased workers’ compensation premiums.

“I believe that the extra investment in the 360 Precision Hand Truck will help to create a culture of safety, productivity and risk management that is worth the investment in the employees’ and company’s future.” (Source, Josh Corbin, OTR/L, Workers’ Comp Occupational Therapist)

*Josh Corbin Product Assessment of the Hand Truck 360, 2022